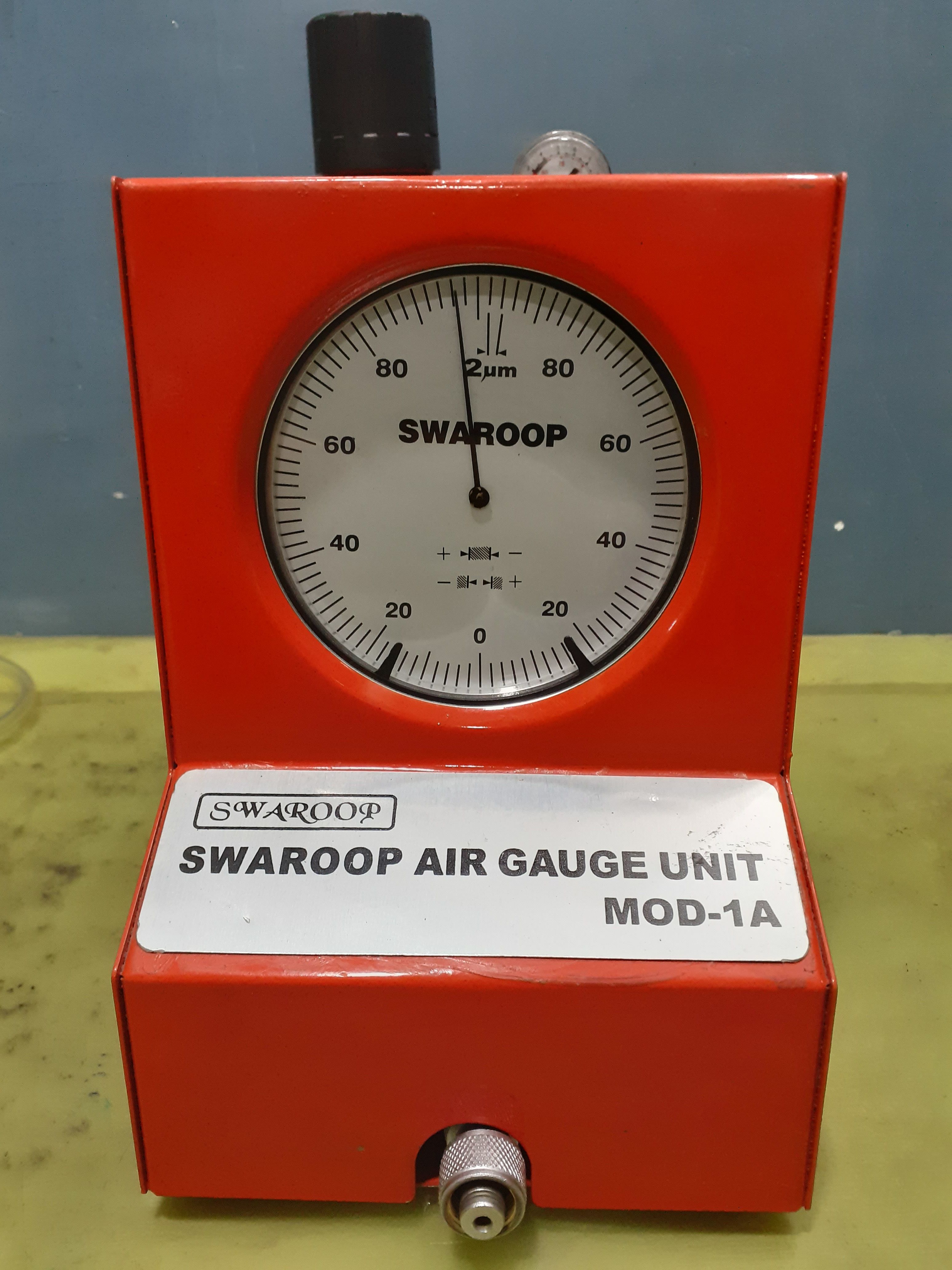

Air Gauge Unit

Price 23000 INR/ Set

Air Gauge Unit Specification

- Sensor Type

- Pneumatic Displacement Sensor

- Measuring Range

- 0.01 mm to 10 mm Rankine

- Bourdon Tube

- Copper Alloy

- Frequency

- 50 Hz Hertz (HZ)

- Case

- Mild Steel Powder Coated

- Glass Size

- 100 mm in Diameter

- Thread

- 1/8 BSP

- Display

- Analog Dial

- Outer Size

- 120 mm x 180 mm

- Material

- Mild Steel / Brass

- Working Presssure

- 2 to 4 Bar

- Seal Material

- Nitrile Rubber (NBR)

- Grade

- Industrial

- Application

- Other

- Accuracy

- 1% of Full Scale gm

- Protection Class

- IP54

- Air Consumption

- Less than 50 ltr/hr

- Mounting Type

- Panel Mount or Bench Top

- Connection Type

- Side or Bottom Entry

- Weight

- Approx 1.2 kg

- Dial Color

- White with Black Markings

- Finish

- Smooth Powder-Coated

- Operating Temperature

- 5 to 50C

Air Gauge Unit Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 250 Sets, , Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Air Gauge Unit

Our provided High Air Gauge Unit gives an efficient response and quick self-cleaning of gauging area. Each system is designed with flow control valves and knob on each side to set air gauge unit. Working on range of 3-4 kg/cm2, this system allows non-contact and high-speed gauging due to less friction. Two masters of this system ensure accurate magnification while measuring intermediate via a self-balance unit. It is manufactured using top-notch quality components and ultra-modern technologies. By the means of this High Air Gauge Unit, you can measure dimensions with ease and high accuracy.

Technical Specification

|

Accuracy |

+/-2% |

|

Air pressure requirement |

4-10kg / cm2 |

|

Working pressure |

51 PSI /3.5kg / cm2 |

|

Country of Origin |

Made in India |

|

Least Count |

0.002 mm |

|

Model Name/Number |

MOD-1 |

|

Brand |

Swaroop |

|

Material |

Mild Steel |

|

Measuring Range |

+/- 0.080 mm |

Precision Engineering for Industrial Applications

Designed for the dimensional measurement of critical mechanical components, this air gauge unit delivers reliable results with 1% full-scale accuracy. Its copper alloy Bourdon tube, brass/mild steel build, and NBR seals provide robust performance even under rigorous conditions. Suitable for applications requiring both repeatability and precision.

User-Friendly and Versatile Design

Select either side or bottom entry connection, and mount the unit on a panel or use it bench-top, as needed. The analog dial display with a clear white face and bold black markings ensures easy reading, while its compact size (120 mm x 180 mm) makes it suitable for diverse workshop layouts.

FAQs of Air Gauge Unit:

Q: How does the air gauge unit achieve precise dimensional measurements?

A: The air gauge unit uses a pneumatic displacement sensor to detect minute differences in dimensions, displaying measurements on an accurate analog dial. This system provides a high level of precision within a range of 0.01 mm to 10 mm, making it ideal for quality control in industrial processes.Q: What are the advantages of the IP54 protection class for this device?

A: IP54 protection means the unit is safeguarded against limited dust ingress and water splashes from any direction. This makes it suitable for use in typical industrial environments where exposure to dust and moisture is common.Q: Where can the air gauge unit be installed for optimal use?

A: Thanks to its flexible mounting types, the air gauge unit can be fixed onto a panel or placed on a bench top. This versatility allows it to be integrated easily into both new and existing workstations in manufacturing or inspection setups.Q: When is this type of gauge most beneficial during the manufacturing process?

A: The air gauge unit is particularly advantageous during the inspection stage, where accurate dimensional verification is necessary. Its fast, non-contact measurement enhances quality assurance without risk of part damage.Q: How should the unit be connected for use with existing equipment?

A: The device supports both side and bottom entry connections, using a standard 1/8 BSP thread. Simply match the thread specifications of your system and choose the entry type that best fits your setup for seamless installation.Q: What are the primary benefits of using an air gauge over contact-based gauges?

A: Air gauges offer non-contact measurement, reducing the risk of wear or deformation of sensitive workpieces. They also provide fast, repeatable results and are less affected by operator skill, ensuring consistent quality checks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Unit Gauge Category

Air Depth Collar Gauge

Price 1 INR / Set

Minimum Order Quantity : 1 Set

Working Presssure : Up to 10 Bar

Material : Stainless Steel / Brass

Measuring Range : 0150 mm

Air Plug Collar Gauge

Price Range 300.00 - 800.00 INR / Set

Minimum Order Quantity : 1 Set

Working Presssure : Up to 10 bar

Material : Steel body, Hardened steel contacts

Measuring Range : 6100 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS